All figures on this page rely to the 99' Discovery version

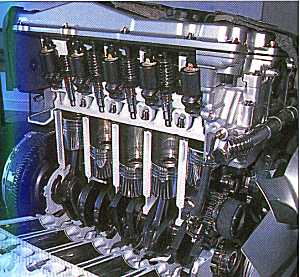

This is a completely new engine. It's codename is Storm but the vehicles are labeled "Td5". (Why, if they had such a nice name?)

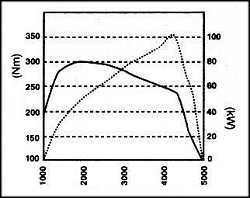

No, it's not an BMW engine, but an Rover design and, as it was almost finished when BMW took over, they agreed to continue work to fit it in Landrovers. It's an 5-cylinder engine, 2498 cc displacement, designed for 4x4 use. It has 300 Nm(manual box)/232 lb-ft of torque at 1950 rpm and 136bhp at 4200 rpm. Those numbers differ considerably on the Defender range, I'm still trying to find out what causes this. It revs to a governed load speed of 4850 rpm (5460 max possible rpm) which is nice for fast driving.

The Lucas injection system is an high pressure system, working at 1500 bars (22.000 psi) and is camshaft driven with a separate plunger pump for each injector. So the pressure is developed in each injector and you have no problems with the fuel lines and fittings. The high pressure allows such a fine fuel evaporation that the Td5 doesn't need an exhaust catalyzer. Knock is reduced further by an pilot injector in each cylinder that advances the flame front at idle. In this way the Td5 is remarkably quiet for a diesel.

A new and very nice feature is the use of an centrifugal oil filter beside the normal filter. This cleans the oil by centrifugal force and accumulates dirt in an disposable metal pot that must be replaced every 36.000 miles (57000 km). In this way oil and standard filter exchange intervals have been extended to 12.000 miles.

NB. This centrifugal system is not new. Old Series cars had it in their oil bath air filter.

5-cylinder

Cast iron with aluminium sump and rocker cover

OHC with single rocker ramp

Hydraulic lifters

Electronic unit injectors

Cam and oil pump chain driven (what happened to the silly rubber timing belt??)

Internal aluminium ladder frame reinforcing the bloc

Centrifugal oil filter

Integrated oil cooler with thermostat (72°C)

New engine management system

Pressure relief system

Vacuum pump integrated to the alternator

Oil valves that spit oil on the downside of the pistons for cooling. The bloc is not fitted to an adaptor plate but mounts directly to the gear box. The oil sump is sealed by an rubber seal with integrated metal space holders so it can't be overcompressed. The crank has laminated connections and can NOT be machined to an undersize. No different size main bearings are available- obviously. The pistons are outside coated with graphite and cooled by oil from below. The flywheel is an "double mass" type- this means a part of the weight is mounted on a spring inside the flywheel. This reduces greatly the shocks by the combustion strokes on idle and low rpms. The flywheel has a similar system with indexing holes as on the V-8 (look there for pics). In difference it only has 31 holes with 5 missing holes at individual distances so the ECM always knows on which position the engine is exactly.

The cylinder head is heat treated and can't be machined down for this reason. It has only 4 preheating plugs (#5 doesn't have one) (WHY?). The rockers are used to generate the extremely high pressure needed for the fuel injection internally. If removed they MUST BE STORED IN UPRIGHT POSITION. Due to the extreme pressure the fuel has to be filtered better than before, the smallest drop of water or dirt will distroy them.

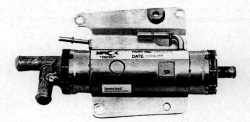

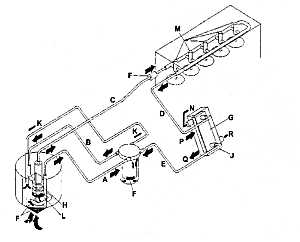

The fuel return line has an fuel cooler to get the fuel back to about 70°C (it gets hot by the extreme pressure in the injectors). The fuel pump for the relative low pressure to feed the lines is made by an 2-stage pump inside the tank. From there it goes to the silliest place, the fuel filter, situated on the outside chassis real just behind the rear wheel!!!! (Picture below taken from the rear right side on a 99' Discovery) On Defenders it's protected by a thin sheet of metal, couldn't find out why they didn't mount a serious protection. Any lump of wood will cut right true it.

A guarantee to get knocked of. Or to freeze in cold weather! The fuel returns to the pump, gets again pressurized to 4 bars and then only goes to the engine. Here it comes to a second fuel filter which should normally never needing replacement. Clean fuel is vital for the injectors working under the extreme pressures.

The oil pump is turned by the distributor chain and has no serviceable parts with the exception of the relief valve spring.

The Injectors are sealed by an copper ring and an O-ring. Both must be replaced each time an injector is taken off. The injectors themselfs are very sensible, especially on the tip. You can throw them away if you once get dirt inside the fuel line, so take extreme care! Also make absolutely sure there's not the smallest dirt particle on the seat when you remount them. If in the slightest doubt, leave it to the dealer. If he messes it up, it's HIS problem.

The timing chain is made of 56 elements, 3 of them are copper color. Refer to the Manual for the exact setting of the chain.

The oil system had to be redesigned as modern engines produce particles smaller than the 15 microns the standard filter can trap. So LR made an centrifugal filter that can trap much smaller particles in his housing and also greatly increase filter life. The filter element can turn with up to 15000 rpm.

The turbo is an Garrett GT20 with electronic modulated discharge valve. Usual precautions must be taken: Switch engine off only after 15 seconds.

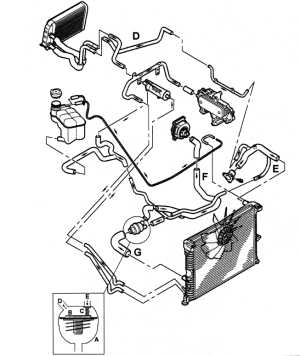

The cooling system uses the usual 50/50 mixture- about 10 liters. See the manual for correct purging instructions. It's not enough to fill up and drive on.

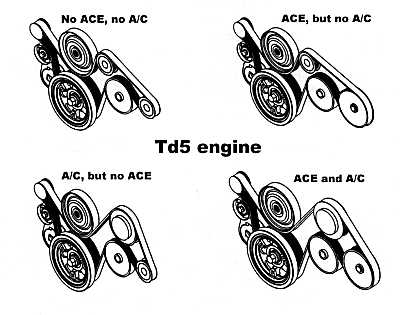

Auxiliary equipment is driven by a Poly-V belt. This here shows the Discovery version, the 90 still doens't have an ACE-system.

Inertial shock sensors are mounted on the bulkhead near the turbo. It senses a sudden deceleration in case of an accident and will shut off fuel supply. The car will not start again if the sensors are not rearmed. Might be a problem if this happens somewhere at the end of the world...

The ECM senses if there's a need to preheat the glow plugs. The indicator light is NOT a sure indicator for it's functioning. The glow plugs reach 1000°C and are also used always when engine is cold- this means they don't stop working once the engine started. They are shut off by the water temp indicator giving a signal to the ECM or after a certain time passed. All this helps in reducing emissions. Seems effective as no more power-robbing catalizers are mounted.

An unusual feature is that the ECM shuts off the fuel line- not the driver by his ignition key. So the shutoff may take between 15 seconds under normal conditions and up to several minutes on a very hot engine!

1. Shut off

2. Wait 15 seconds

3. Turn key to position 2 (contact)

4. Wait 30 seconds

5. Shut off for 5 seconds

Repeat this 4-5 times so the air gets purged out

1. Floor the right pedal

2. Let the starter turn for 30 seconds

If it did not yet start, wait and let the starter cool down. When the ECM does not detect a running engine after 10rotations of the crank, it goes to purge mode. Now it injects 4 times as much fuel as under maximum conditions allowed. Do use this sequence only when out of fuel as else it risks to drown the engine.

For ECM procedures please refer to the V-8 section on these pages